Basket Strainers & Bucket Strainers Your Premier Source For Strainer Solutions

Our Simplex and Duplex Basket Strainers are engineered for optimal performance ensuring your operations run smoothly and efficiently.

As the leading provider of strainer solutions Purple Engineering offers an extensive range of basket strainers designed to meet the diverse needs of modern industries.

Simplex Basket Strainers: Essential Protection For Your Systems

Our Simplex Basket Strainers are designed for reliability and ease of maintenance, making them ideal for applications where periodic shutdowns for basket cleaning are possible. They provide excellent protection for pumps, valves, traps, and other mechanical equipment. With clean baskets, these strainers maintain the integrity of your fluid handling systems, ensuring contaminant-free operations.

Key Features:

- Robust construction for durability

- Easy cleaning through a valve or plug connected to the blow-off outlet

- Suitable for a wide range of applications, including water systems, compressors, and lubrication systems

Request a Quote for Basket Strainers

Duplex Basket Strainers: Uninterrupted Filtration For Critical Operations

For systems where the flow cannot be shut down for basket cleaning, such as cooling water systems, fire lines, fuel lines, and marine applications, our Duplex Basket Strainers are the perfect solution. These strainers allow for continuous operation with a dual-chamber design that facilitates seamless switching between baskets for cleaning without interrupting the process flow.

Key Features:

- Continuous operation with no downtime

- Dual-basket design for easy maintenance

- Ideal for critical applications in cooling water, condensers, and fuel systems

Why Choose Purple Engineering?

- Wide Range of Options: From Simplex and Duplex Strainers to specialised options like JIS Marine Basket Strainers, Fabricated Basket Strainers, and Custom Made Basket Strainers, we offer solutions tailored to your specific needs.

- Material Selection: Our strainers come in various materials, including 304LSS, LTC.S, and special alloys, ensuring compatibility with your operational environment.

- Expertise and Quality: With a focus on quality and innovation, Purple Engineering is dedicated to providing strainers that enhance the efficiency and reliability of your operations.

Explore Our Basket Strainer Solutions:

- Simplex Basket Strainers

- Duplex Strainers

- JIS Marine Basket Strainers

- Fabricated Basket Strainers

- Replacement Strainer Baskets and Screens

- Custom Made Basket Strainers

- Special Alloys Basket Strainers

Get In Touch

Enhance your filtration process with Purple Engineering's basket strainers. Contact us today to find the perfect strainer solution for your operation. Let us be your partner in achieving operational excellence and protecting your processes.

Purple Engineering - The Leading Source for Strainer Solutions

Basket Strainers Your Premier Source For Strainer Solutions

ACE-BS35-CS

Basket Strainer, Carbon Steel A216 Gr. WCB, ANSI Class 300, Threaded, Bolted or Quick Open Cover, Epoxy Painted

ACE-BS35-SS

Basket Strainer, Stainless Steel A351 Gr. CF8M, ANSI Class 300, Threaded, Bolted or Quick Open Cover

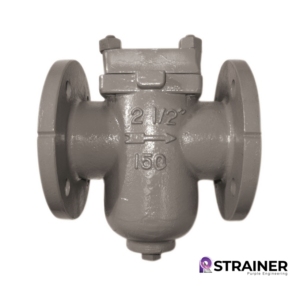

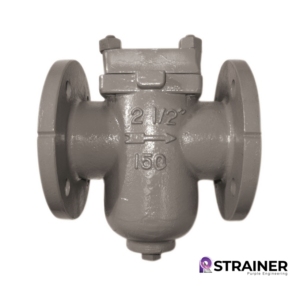

ACE-BS35F-CS

Basket Strainer, Carbon Steel, ASME Class 150, Flanged, Bolted or Quick Open Cover, Epoxy Painted

BS25-CI

Basket Strainer, Cast Iron, ASME Class 125, Threaded, Bolted or Quick Open Cover, Epoxy Painted

BS25F-CI

Basket Strainer, Cast Iron, ASME Class 125, Flanged, Bolted or Quick Open Cover, Epoxy Painted

BS65-CI

Product Description: Basket Strainer, Cast Iron, ASME Class 125, Flanged, Bolted Cover, Epoxy Painted

BS85-CS

Product Description: Basket Strainer, Carbon Steel, ASME Class 150, Flanged, Bolted Cover, Epoxy Painted

BS85-SS

Product Description: Basket Strainer, Stainless Steel, ASME Class 150, Flanged, Bolted Cover

BS86-CS

Product Description: Basket Strainer, Carbon Steel, ASME Class 300, Flanged, Bolted Cover, Epoxy Painted

BS86-SS

Product Description: Basket Strainer, Stainless Steel, ASME Class 300, Flanged, Bolted Cover

Model 72

Perfect for Industrial and commercial applications in which the line can be temporarily shut down for strainer basket cleaning or changeout.

Model 72L Tefzel Plastic Lined

A continuous lining of advanced fluoropolymer resin makes the Model 72L simplex strainer an excellent, low-cost alternative to exotic alloy strainers in a wide variety of corrosive or abrasive lined piping applications. The basic design is that of our popular time-tested Model 72.

Model 72SJ Steam Jacketed

Model 72SJ Steam jacketed strainers are used for applications where materials must be kept hot in order to remain fluid. Applications examples are chocolate, asphalt, resins, and polymers.

Mueller 125-CI

Designed for large capacity straining on cooling water, seawater, hot water systems, and other similar applications, the Series 125 strainer ensures your pipelines remain clear of foreign matter.

Mueller 125-CS

Designed for chemical process applications including brine, paint, fuel oil, organic and inorganic chemicals, condensers, heat exchangers, and other similar applications.

Mueller 125-SS

Our Class 150 basket strainers are designed for chemical process applications including brine, paint, fuel oil, organic and inorganic chemicals, condensers, heat exchangers, and other similar uses.

Mueller 125F-B

Class 150 cast iron flanged end basket strainers are designed for use with cooling water, seawater, hot water systems, and other applications.

Mueller 125F-CI

Designed for use with cooling water, seawater, hot water systems, and more, our Class 125 cast iron flanged end basket strainers provide essential protection for costly pumps, meters, valves, and other mechanical equipment.

Mueller 125F-CS

Our Class 150 Carbon Steel flanged end Simplex basket strainers, model 125F-CS, provide economical protection for costly pumps, meters, valves, and other mechanical equipment.

Mueller 125F-SS

Model 125F-SS, provide economical protection for costly pumps, meters, valves, and other mechanical equipment by straining foreign matter from pipelines.

Mueller 126F-CS

The model 126F-CS, provide economical protection for costly pumps, meters, valves, and other mechanical equipment by straining foreign matter from pipelines.

Mueller 126F-SS

The model 126F-SS, provide economical protection for costly pumps, meters, valves, and other mechanical equipment by straining foreign matter from pipelines.

Mueller 155M

Our high-capacity Cast Iron flanged end basket strainers, model 155M, are designed for high-flow applications such as swimming pool installations.

Mueller 165-B

The model 165-B aluminium bronze basket strainer designed for applications such as cooling water, seawater, hot water systems, and more.

Mueller 165-CI

The model 165-CI, provide economical protection for costly pumps, meters, valves, and other mechanical equipment by straining foreign matter from pipelines.

Mueller 166-B

The model 166-B aluminium bronze basket strainer is designed for applications such as cooling water, seawater, hot water systems, and more.

Mueller 166-DI

The model 166-DI Ductile Iron flanged end basket strainers, are designed for applications such as cooling water, seawater, hot water systems, and more.

Mueller 185-CS

Our 185-CS Class 150 Carbon Steel flanged end basket strainers are designed for brine, paint, fuel oil, organic and inorganic chemicals, as well as condensers and heat exchangers.

Mueller 185-SS

The 185-SS Stainless Steel flanged end basket strainers, designed for chemical process applications, including brine, paint, fuel oil and other similar applications.

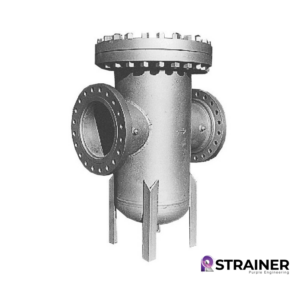

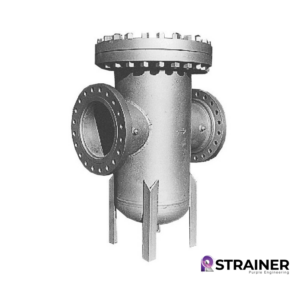

Mueller 185FAB-B

The 185FAB-B Fabricated flanged end basket strainers are designed to remove foreign particles from pipelines, providing protection for pumps, valves, and similar costly equipment.

Mueller 185FAB-Q

The model 185FAB-Q Fabricated flanged end basket strainer designed to remove foreign particles from pipelines.

Mueller 186-CS

The 186-CS Class 300 Cast Carbon Steel flanged end basket strainers are designed for chemical process applications.

Mueller 186-SS

The 186-SS Stainless Steel flanged end basket strainers, designed for chemical process applications, including brine, paint, fuel oil and other similar applications.

Mueller 186FAB-B

The 186FAB-B Fabricated flanged end basket strainers are designed to remove foreign particles from pipelines, providing protection for pumps, valves, and similar costly equipment.

Mueller 595-CI

The model 595-CI Cast Iron flanged end basket strainer, designed exclusively to prevent clogging in fire service systems.