Optimal Filtration with Versatile Design Discover the Efficiency of Tee Strainers with Purple Engineering

At Purple Engineering, Australia's leading provider of Tee Style Strainers, we combine efficiency with innovation to meet your filtration needs. Our Tee Strainers, also known as T Strainers, are designed to provide superior protection for your pipelines and equipment, ensuring your systems operate smoothly and efficiently.

Why Tee Strainers?

Tee Strainers are named for their T-shaped design, offering a compact and efficient solution for removing particles and debris from fluid systems. Ideal for a wide range of applications, these strainers are especially suited for conditions where space constraints or specific piping configurations necessitate a versatile and effective filtration solution.

Our Range of Tee Style Strainers

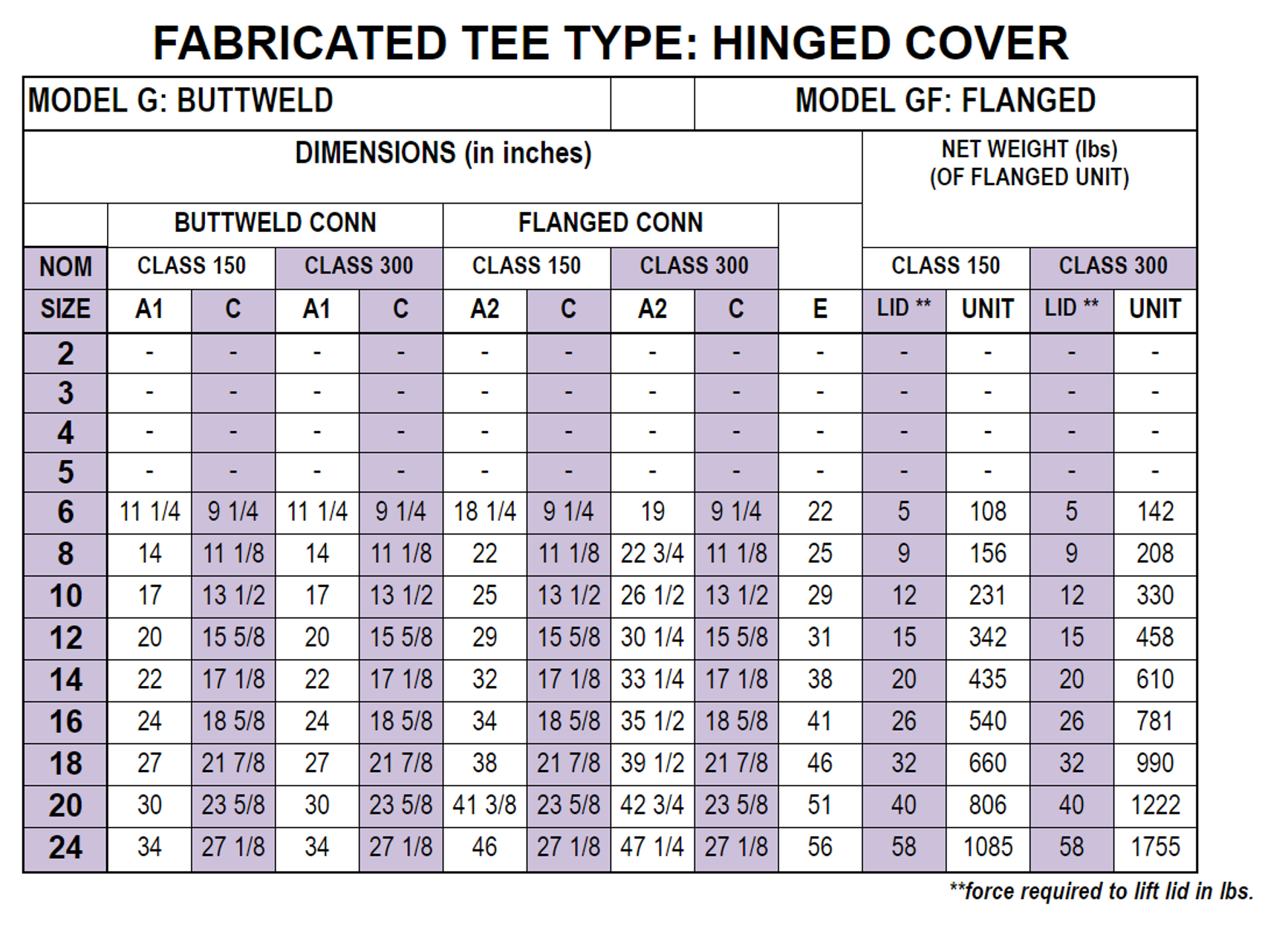

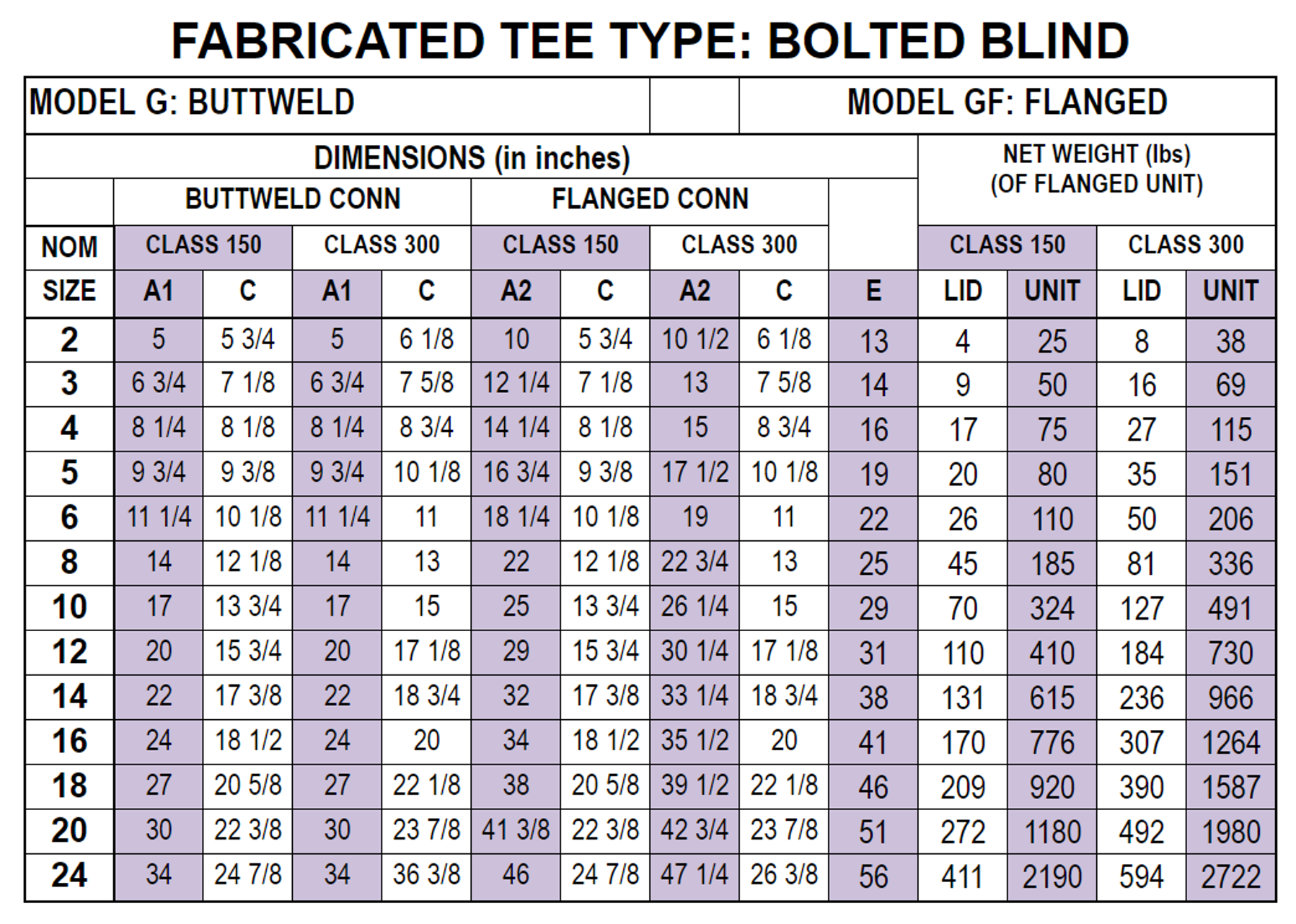

Our Tee Style Strainers are available in sizes ranging from 2" to 24", with options for both bolted and hinged covers to suit various maintenance preferences and system requirements. This versatility ensures that you can find the perfect strainer to match the specific needs of your operation, whether you're dealing with water, oil, gas, or other fluids.

Request a Quote for Tee Strainers

Key Features:

- Versatile Design: The T-shaped configuration allows for easy integration into existing piping systems, making them ideal for both new installations and upgrades.

- Efficient Filtration: Designed to trap a wide range of particulates, ensuring the protection and longevity of downstream equipment.

- Easy Maintenance: Available with bolted or hinged covers for quick and easy access to the strainer basket for cleaning or replacement.

- Durable Construction: Manufactured from high-quality materials to withstand various operating conditions and ensure a long service life.

Applications

Tee Strainers are used across various industries, including but not limited to:

- Chemical processing

- Oil and gas production

- Water treatment facilities

- Power generation

- Food and beverage manufacturing

Why Choose Purple Engineering for Your Tee Strainers?

- Expertise: As the largest provider of Tee Style Strainers in Australia, we have the knowledge and experience to offer solutions that meet your specific requirements.

- Quality: Our commitment to quality ensures that every strainer we provide is designed to perform reliably under the conditions it's intended for.

- Customisation: Understanding that every system has unique needs, we offer customisation options to ensure your strainer perfectly matches your application.

- Support: Our team is dedicated to providing exceptional support, from product selection to after-sales service.

Get in Touch with Purple Engineering

Elevate the efficiency and reliability of your fluid systems with our Tee Strainers. Contact Purple Engineering today to discuss your requirements and discover how our solutions can enhance your operations. Our team is ready to assist you in selecting the perfect strainer solution tailored to your specific needs.

Purple Engineering - Your Trusted Partner in Advanced Filtration Solutions.

Tee Strainers Your Premier Source For Strainer Solutions

Mueller 46T

The Mueller 46T Tee Strainer is expertly engineered to ensure the integrity and efficiency of fluid handling systems by removing foreign particles from pipelines.

Mueller 44T

The Mueller 44T Tee Strainer is expertly engineered to ensure the integrity and efficiency of fluid handling systems by removing foreign particles from pipelines.

Mueller 42T

The Mueller 42T Tee Strainer is expertly engineered to ensure the integrity and efficiency of fluid handling systems by removing foreign particles from pipelines.

Mueller 41T

The Mueller 41T Tee Strainer is designed for use in fluid handling systems to remove foreign particles from pipelines.

Quick Opening ACE-FT33-300

Versatile and durable filtration system engineered to meet the rigorous demands of industrial environments.

Quick Opening ACE-FT23-150

The ACE-FT23-150 is a robust solution tailored for the demanding filtration needs across various industries.

Quick Opening ACE-FT34-300

Engineered to address the filtration needs of industrial applications with precision and adaptability.

Quick Opening ACE-FT24-150

Engineered to address the filtration needs of industrial applications with precision and adaptability.

Bolted Cover ACE-FT50-900

Designed to meet the specific needs of industrial filtration with a focus on practicality and efficiency.

Bolted Cover ACE-FT40-600

Prepared to tackle various operational challenges, complemented by the availability of special coatings and linings to enhance durability and performance

Bolted Cover ACE-FT30-300

The ACE-FT30-300 is a superior filtration solution tailored to the rigorous demands of industrial environments.

Bolted Cover ACE-FT20-150

Distinguished by its robust selection of materials, capable of withstanding diverse operating environments.