In the industrial landscape, the protection and maintenance of equipment are paramount for ensuring operational efficiency, safety, and longevity.

Strainers, often overlooked as simple components, play a crucial role in safeguarding critical machinery from potential damage caused by debris and particulate matter.

This comprehensive article explores how the correct use of strainers prevents damage to downstream equipment, significantly reduces maintenance costs, and enhances system efficiency.

The Critical Role of Strainers in Industrial Systems

Strainers are essential in various industrial processes, acting as the first line of defence against the ingress of foreign particles into equipment. By filtering out debris, strainers prevent clogs, wear, and damage to sensitive components downstream, such as pumps, compressors, heat exchangers, and valves. Choosing the proper strainer with the appropriate material and size for the specific application cannot be overstated.

Preventing Damage and Extending Equipment Life

Particles and debris in fluid or gas streams can cause significant damage to industrial equipment. Abrasive particles can erode internal surfaces, while larger debris can cause physical blockages, leading to overheating, increased pressure, and eventual breakdown. Strainers remove these harmful particles before they reach critical components, extending the equipment’s operational life and reducing the likelihood of unscheduled downtime.

Reducing Maintenance Costs

Routine maintenance is a significant expense in industrial operations, often involving the cleaning, repairing, or replacing parts damaged by debris. Installing appropriate strainers minimises the need for frequent maintenance by keeping the system clean. This saves on the direct costs associated with parts and labour and reduces the downtime required for maintenance activities, further saving indirect costs related to lost production.

Improving System Efficiency

The presence of debris in a system can significantly impair its efficiency. For example, particulate matter in a heat exchanger can reduce thermal transfer efficiency, while debris in a pump can decrease flow rates and increase energy consumption. By ensuring a cleaner system, strainers help maintain optimal efficiency, leading to energy savings and improved performance.

Types of Strainers and Their Cost-Saving Benefits

Basket and Duplex Strainers

Basket strainers are ideal for applications where large particles must be removed, and the system can be temporarily shut down for cleaning. Duplex strainers, with their dual-basket design, allow for continuous operation by enabling the cleaning of one basket while the other is in use, which is ideal for processes where shutdown is not feasible.

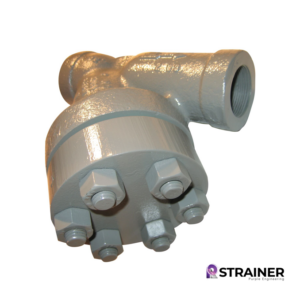

Y and Tee Strainers

Y strainers, suitable for smaller particles, and Tee strainers, designed for space-constrained environments, effectively protect components in piping systems. Their simple design and ease of maintenance make them cost-effective solutions for a wide range of applications.

Self-Cleaning and Temporary Strainers

Self-cleaning strainers offer automated debris removal, reducing manual cleaning efforts and ensuring uninterrupted protection. Temporary strainers are used during system start-up to catch debris left from construction, protecting the system from initial contamination.

Case Studies: Cost Savings in Action

Real-world applications demonstrate the value of strainers in protecting equipment and saving costs. In one case, a manufacturing facility experienced frequent pump failures due to particulate ingress. After installing appropriate basket strainers, pump life extended significantly, and maintenance costs dropped by 30%.

In another instance, a chemical processing plant utilised duplex strainers to maintain continuous operation during batch processes, reducing downtime and increasing production efficiency by 20%.

Conclusion

The strategic use of strainers in industrial systems is a testament to the adage that prevention is better than cure. By filtering out debris and preventing it from reaching critical components, strainers play an indispensable role in protecting equipment, reducing maintenance costs, and enhancing operational efficiency.

The initial investment in the proper strainers pays dividends through extended equipment life, reduced downtime, and overall cost savings. As industries seek ways to optimise operations and reduce expenses, the importance of strainers in achieving these goals cannot be underestimated.

For information or advice about Strainers, contact our team today.