Duplex strainers are engineered to provide a seamless and uninterrupted filtration process, which is crucial for operations where continuous flow is a non-negotiable requirement.

Their unique design allows for the simultaneous operation of two filtration chambers, one active and one on standby, ensuring that fluid processing does not halt for maintenance or cleaning.

This article delves into duplex strainers’ design and operational advantages, highlighting their significance in industries where any interruption can lead to significant operational inefficiencies or safety concerns.

Design Features of Duplex Strainers

Dual Chamber Configuration

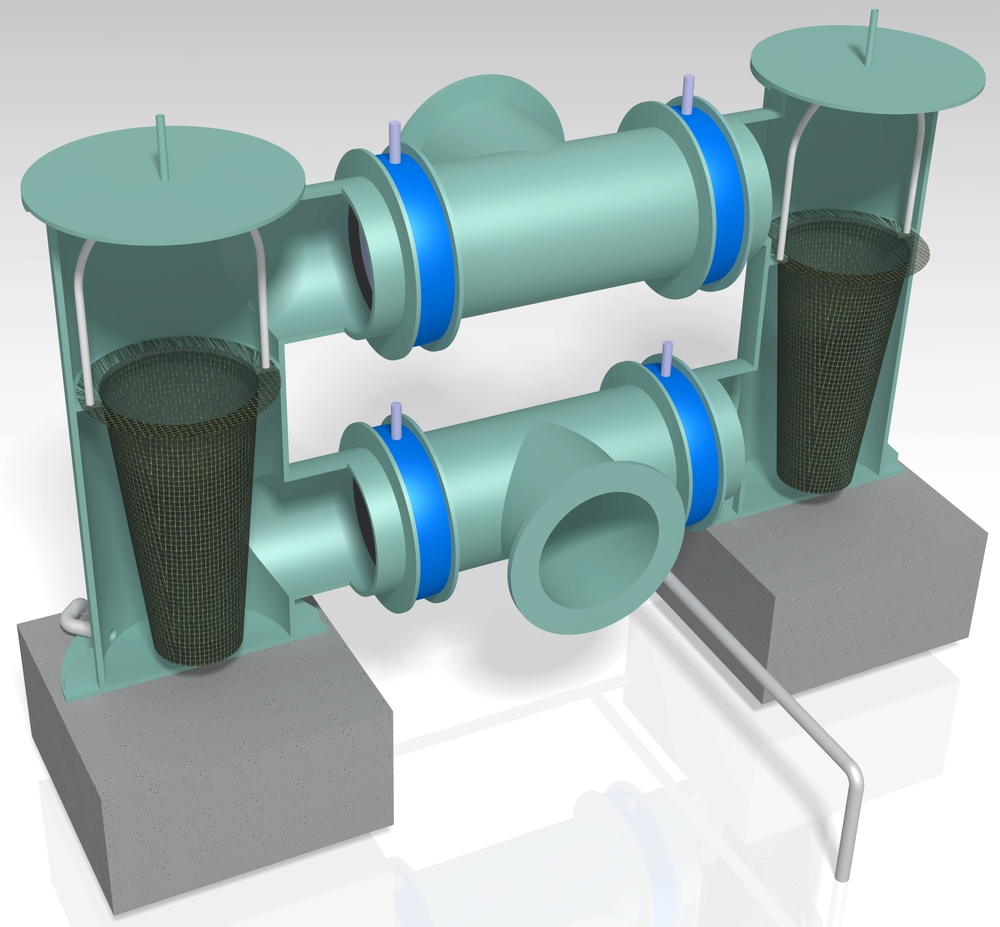

The cornerstone of the duplex strainer’s design is its dual chamber configuration, which houses two separate strainer baskets. This setup allows one basket to be in use while the other is being cleaned or replaced, ensuring that the flow of the process medium is not interrupted.

Diverter Valve System

A diverter valve is central to the operation of a duplex strainer, allowing the flow to be switched from one chamber to the other without stopping the process. Depending on the system’s requirements, this valve can be operated manually or automatically, providing flexibility and ease of use.

Easy Access for Maintenance

Duplex strainers are designed with maintenance in mind. Access to the strainer baskets for cleaning or replacement is straightforward, minimizing downtime and ensuring that operations can resume quickly.

Operational Advantages

Uninterrupted Flow

The primary advantage of duplex strainers is their ability to maintain an uninterrupted flow, which is critical in many industrial processes. Industries such as chemical manufacturing, oil and gas, power generation, and pharmaceuticals, where continuous operations are essential, benefit significantly from the installation of duplex strainers.

High Reliability

With two strainer baskets available, duplex strainers offer a redundancy that enhances the reliability of the filtration system. Even if one basket becomes completely clogged, the system can continue to operate effectively, providing an additional layer of security against operational disruptions.

Versatility and Adaptability

Duplex strainers can accommodate a wide range of process fluids, temperatures, and pressures, making them suitable for various applications. They can be customized with different basket materials and mesh sizes to meet specific filtration requirements, adding to their versatility. Having the options to be made in carbon steel or stainless steel, vastly expand their application.

Efficiency and Cost Savings

By ensuring continuous operation, duplex strainers help to optimize process efficiency and reduce the potential for costly downtime. Cleaning or replacing baskets without halting the process also contributes to operational cost savings over time.

Industries Where Duplex Strainers Are Crucial

Oil and Gas

In the oil and gas industry, where the continuous flow of crude oil, natural gas, and process chemicals is essential, duplex strainers ensure that operations proceed without interruption, safeguarding against costly shutdowns and equipment damage.

Chemical Processing

Chemical manufacturing processes often involve corrosive or abrasive fluids that must be filtered continuously to protect equipment and ensure product quality. Duplex strainers provide the necessary uninterrupted filtration to maintain these critical operations.

Power Generation

For power plants, especially those operating on a continuous cycle, duplex strainers are vital in cooling water systems and fuel supply lines, ensuring that turbines and other critical components are protected from particulate matter.

Pharmaceutical Manufacturing

In pharmaceutical production, where contamination can compromise product purity and safety, duplex strainers ensure that process liquids are continuously filtered without risking production halts for basket cleaning or replacement.

Conclusion

Duplex strainers represent a critical solution for industries where uninterrupted flow and operational continuity are paramount. Their dual-chamber design and easy maintenance features ensure that processes remain operational, even during filtration basket cleaning or replacement.

By providing a reliable, continuous flow in critical operations, duplex strainers protect equipment and enhance overall process efficiency, making them an indispensable component in various industrial applications.

To find out more or to request a quote for Duplex Strainers to suit your application, contact the team at Strainer today.