Strainers play a crucial role in various industries by protecting equipment from particulate matter and ensuring the purity of fluids in processes. The appropriate strainer type per application is pivotal for operational efficiency, equipment longevity, and process reliability.

This guide provides an overview of the best strainer types suited for different sectors, including oil and gas, water treatment, manufacturing, and more, offering specific examples and recommendations to aid in the selection process.

Oil & Gas Industry

Recommended Strainers:

- Duplex Strainers: Ideal for continuous operations where the process cannot be stopped for strainer cleaning. Their dual-basket system allows one basket to be cleaned while the other is in use, ensuring uninterrupted flow.

- Y Strainers: Suitable for protecting pumps, valves, and similar equipment from particulate matter. They are commonly used in less critical applications where occasional cleaning is feasible.

Material Considerations:

- Materials: Super duplex stainless steel or Hastelloy for corrosion resistance in harsh environments.

Water Treatment

Recommended Strainers:

- Automatic Self-Cleaning Strainers: Essential for applications requiring continuous operation and minimal maintenance. They are particularly useful in intake and pre-filtration stages to remove debris from natural water sources.

- Basket Strainers: Often used in smaller or less critical applications within the plant for removing larger debris.

Material Considerations:

- Materials: Fiberglass-reinforced plastic (FRP) and stainless steel are common for their corrosion resistance and durability in aquatic environments.

Manufacturing (General)

Recommended Strainers:

- Simplex Basket Strainers: A versatile choice for various manufacturing processes, offering ease of maintenance and sufficient protection against particulate matter.

- Y Strainers: An economical option for less critical applications, suitable for protecting equipment from larger particles.

Material Considerations:

- Materials: Cast iron or carbon steel for systems not exposed to corrosive materials; stainless steel for corrosive environments.

Chemical Processing

Recommended Strainers:

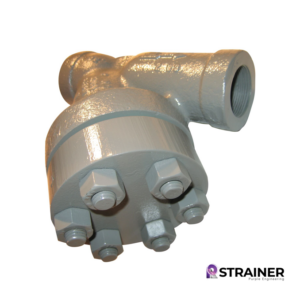

- Tee Strainers: Customizable to handle high pressures and corrosive materials, tee strainers are suitable for protecting sensitive components in chemical processing lines.

- Duplex Strainers: For continuous operations involving aggressive chemicals, ensuring process integrity without interruption for cleaning.

Material Considerations:

- Materials: Hastelloy or titanium for extreme corrosion resistance.

Food & Beverage

Recommended Strainers:

- Sanitary Strainers: Designed to meet strict hygiene standards, these strainers are used in food and beverage processes to ensure product purity and safety.

- Self-Cleaning Strainers: For applications requiring high levels of cleanliness and minimal downtime.

Material Considerations:

- Materials: High-grade stainless steel (e.g., 316L) for corrosion resistance and ease of cleaning.

Power Generation

Recommended Strainers:

- Y Strainers: Commonly used in cooling water systems and for protecting pumps and valves from debris.

- Automatic Self-Cleaning Strainers: Ideal for cooling towers and boiler feedwater applications where continuous operation is critical.

Material Considerations:

- Materials: Depending on the specific application, materials range from carbon steel for freshwater systems to super duplex stainless steel for seawater applications.

Pharmaceuticals

Recommended Strainers:

- Sanitary Strainers: Essential for ensuring the purity of products and processes. They are designed for easy cleaning and sterilisation.

- Duplex Strainers: Used in systems where process continuity is vital and exposure to aggressive cleaning agents may occur.

Material Considerations:

- Materials: High-grade stainless steel with smooth finishes to prevent bacterial growth and contamination.

Conclusion

Selecting the right strainer for your industry involves understanding the specific requirements of your processes, including the nature of the fluids, the type of contaminants, and the operational environment.

By considering the recommended strainer types and material considerations for each sector, you can ensure the protection of your equipment and the efficiency of your operations.

Always consult with strainer manufacturers or specialists like the team here at Strainer to find the most suitable solution for your specific needs, taking into account the latest advancements and innovations in strainer technology.