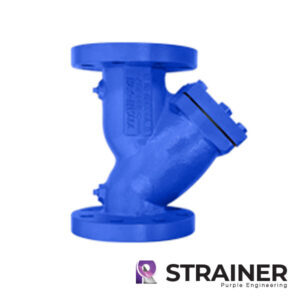

Cast Iron Strainers: Durable Protection for Your Industrial Systems

Robust, Reliable, and Ready to Meet Your Needs

Cast iron strainers provide essential protection for pipelines and equipment across various industries. At Purple Engineering (Strainer), we offer a comprehensive selection of cast iron strainers to suit your specific application:

- In-Stock Options: Choose from popular sizes and pressure ratings for immediate deployment.

- Customisation Solutions: We tailor strainers to your unique flow rates, pressure requirements, and filtration needs.

Benefits of Cast Iron Strainers:

- Durability: Built to withstand demanding conditions.

- Temperature Resistance: Ideal for high-temperature applications.

- Cost-Effectiveness: A budget-friendly option for non-corrosive fluids.

Common Applications:

- Water treatment

- Oil & gas

- Chemical processing

- And many more

Ready to Protect Your Equipment?

- Browse our in-stock cast iron strainers.

- Request a quote for a custom-engineered solution.

Contact us today to discuss your cast iron strainer requirements.

Request a Quote for Cast Iron Strainers

Mueller 911U

The Mueller 911U UL approved Y-Strainer effectively prevents clogging in fire service systems, protecting pumps and mechanical equipment.

Mueller 625-CI

The Mueller 625-CI Turbine Meter Strainer is expertly engineered to ensure the integrity and efficiency of fluid handling systems by removing foreign particles from pipelines.

Mueller 791USA

791USA Duplex Strainer is engineered to provide economical protection for mechanical equipment by straining foreign matter from the connected piping system.

Mueller 791UFA

791UFA Duplex Strainer is designed to provide economical protection by straining foreign matter from the connected piping system.

Mueller 791SA

Series 791SA Duplex Strainer provides economical protection for costly pumps, meters, valves by straining foreign matter.

Mueller 791MFA-SM

The Mueller Steam Specialty Series 791MFA-SM Duplex Smart Strainer is designed for critical fluid handling systems where the flow cannot be stopped for basket cleaning.

Mueller 791FA

The 791FA Duplex Strainer is specifically designed for fluid handling systems where the flow cannot be stopped for basket cleaning.

Mueller 691MFA-SM

691MFA-SM Duplex Smart Strainers provides users with performance data of their duplex strainer, enabling informed decisions for maintenance.

Mueller 691MFA

Our Series 691MFA-SM duplex strainers are designed for fluid handling systems where the flow cannot be shut down for basket cleaning.

Watts 97FB-CI

The model 97FB-CIB Cast Iron flanged end basket strainers, are designed for use in liquid and steam applications.

Mueller 595-CI

The model 595-CI Cast Iron flanged end basket strainer, designed exclusively to prevent clogging in fire service systems.

Mueller 165-CI

The model 165-CI, provide economical protection for costly pumps, meters, valves, and other mechanical equipment by straining foreign matter from pipelines.

Mueller 155M

Our high-capacity Cast Iron flanged end basket strainers, model 155M, are designed for high-flow applications such as swimming pool installations.

Mueller 125F-B

Class 150 cast iron flanged end basket strainers are designed for use with cooling water, seawater, hot water systems, and other applications.

Mueller 125F-CI

Designed for use with cooling water, seawater, hot water systems, and more, our Class 125 cast iron flanged end basket strainers provide essential protection for costly pumps, meters, valves, and other mechanical equipment.

Mueller 125-CI

Designed for large capacity straining on cooling water, seawater, hot water systems, and other similar applications, the Series 125 strainer ensures your pipelines remain clear of foreign matter.

EATON Model 2596 – Cast

Cast Model 2596 Automatic Self-Cleaning pipeline strainers, available in sizes ranging from 2″ to 8″, are offered in both cast iron and stainless steel options.

DS 695-CI

The Cast Iron DS695 Duplex strainer is an essential component designed for high-efficiency filtration in various industrial applications.

ACE-DI

The DS 695 Flanged Duplex Strainer is an advanced and durable solution designed to safeguard system components by efficiently removing debris from processing fluids.

Threaded DS 595 CI

The DS 95 Duplex Strainer is an advanced and durable solution designed to safeguard system components by efficiently removing debris from processing fluids.

YS59-CI

Y Strainer, Cast Iron, ANSI Class 250, Flanged Ends, Extra Heavy Body, Bolted Cover, Epoxy Painted, Plugged Blow-off

YS58-CI

Y Strainer, Cast Iron, ANSI Class 125, Flanged Ends, Bolted Cover, Epoxy Painted, Plugged Blow-off

YS12-CI

Y Strainer, Cast Iron, ANSI Class 250, Threaded Ends, Epoxy Painted, Gasketed Caps, Plugged Blow-off

BS65-CI

Product Description: Basket Strainer, Cast Iron, ASME Class 125, Flanged, Bolted Cover, Epoxy Painted

BS25F-CI

Basket Strainer, Cast Iron, ASME Class 125, Flanged, Bolted or Quick Open Cover, Epoxy Painted