Request a Quote for Chrome Molly

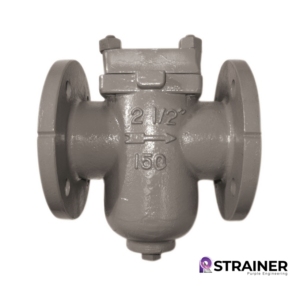

Mueller 863M

The Mueller 863M Cast Carbon Steel and Alloy Steel Y-Strainer offers robust protection for mechanical equipment by straining foreign matter from pipelines.

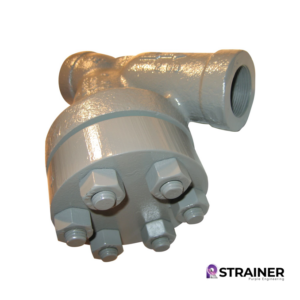

Mueller 865-CS

The Mueller 865-CS Cast Carbon Steel Y-Strainer is designed for high-pressure and high-temperature applications, ensuring protection for pipelines by straining foreign matter and weld debris.