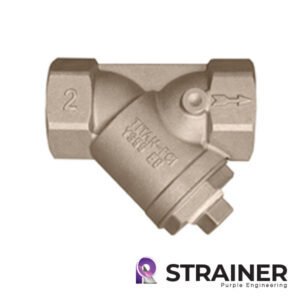

Eco Brass Strainers: Environmentally Conscious Filtration

Sustainable Solutions for Your Systems

Eco Brass strainers offer a balance of strength, corrosion resistance, and environmental responsibility. Made with lead-free brass alloys, these strainers are a safer choice for applications where traditional brass might pose concerns. Purple Engineering (Strainer) is proud to offer Eco Brass strainers as part of our commitment to sustainable solutions.

Advantages of Eco Brass Strainers

- Lead-Free: Compliant with drinking water standards and environmentally responsible.

- Corrosion Resistance: Suitable for water systems and various non-aggressive fluids.

- Strength and Machinability: Similar to traditional brass, allowing for reliable performance and ease of fabrication.

- Recyclable: Contributes to a circular economy and minimizes waste.

Types of Eco Brass Strainers

- Y-Strainers: Versatile and compact for basic filtration in various settings.

- Basket Strainers: Larger filtration area options for heavier debris loads or higher flow rates.

- Custom Designs: Can be tailored to your specific requirements.

Applications for Eco Brass Strainers

- Drinking water and potable water systems

- Food and beverage processing

- Irrigation and landscaping

- Plumbing applications

- Applications where lead reduction is a priority

Choose Sustainable Filtration with Eco Brass

- Browse our Eco Brass strainer options.

- Request a quote for a custom solution.

Contact Purple Engineering (Strainer Australia) and discover how Eco Brass strainers support your filtration needs and environmental goals.