Explore the Pinnacle of Purity with Our Stainless Steel Sanitary Strainers Maintaining Hygiene Standards in Critical Processes

At Purple Engineering, we provide superior stainless steel sanitary strainers that play a crucial role in maintaining the highest levels of purity and efficiency in various industries. Our focus on quality, innovation, and reliability makes us a leader in sanitary filtration, ensuring that your processes meet and exceed the stringent hygiene standards required in the food, beverage, pharmaceutical, and biotech sectors.

Why Sanitary Strainers Are Essential

Sanitary strainers are vital components in any process where contamination control is critical. They are designed to remove particulates and debris from fluids, protect sensitive equipment, and ensure the integrity of your products. By using sanitary strainers, you can prevent costly downtime, extend your machinery's lifespan, and guarantee your output's safety and quality.

Request a Quote for Sanitary Strainers

Applications of Sanitary Strainers

Our sanitary strainers find applications across a broad spectrum of industries, including but not limited to:

- Food and Beverage Production: Ensuring the purity of ingredients and final products.

- Pharmaceutical Manufacturing: Maintaining sterility and preventing contamination in drug production.

- Biotechnology: Protecting sensitive biological processes from particulate matter.

- Dairy Industry: Keeping milk and dairy products free from impurities.

- Cosmetics and Personal Care: Guaranteeing the safety and quality of beauty products.

Materials and Design for Uncompromised Quality

Crafted from high-grade stainless steel, our sanitary strainers offer exceptional resistance to corrosion and are easy to clean, ensuring they meet the hygienic standards of your industry. The design of our strainers prioritises efficiency, with features that allow for easy maintenance and minimal disruption to your operations.

Why Choose Purple Engineering for Your Sanitary Straining Needs?

- Expertise: With years of experience in the filtration industry, we have the knowledge to recommend the perfect straining solution for your specific needs.

- Customisation: We understand that every process is unique. Our team is ready to work with you to customise strainers that fit seamlessly into your operations.

- Quality Assurance: Every strainer we provide is manufactured to the highest standards, ensuring reliability and performance that you can trust.

- Customer Support: From initial consultation to after-sales service, our dedicated team is here to support you every step of the way.

Get In Touch

Don't let contamination compromise the quality of your products or the efficiency of your processes. Contact Purple Engineering today to discover how our sanitary strainers can make a difference in your operations. Our team is ready to assist you in selecting and customising the ideal strainer solution to meet your specific requirements, ensuring purity, efficiency, and reliability.

Purple Engineering - Your Trusted Partner in Advanced Sanitary Filtration.

Sanitary Strainers Your Premier Source For Strainer Solutions

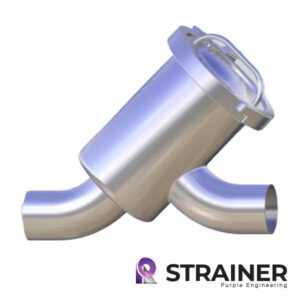

ACE Y Type Sanitary Strainer

For use in the food, beverage, pharmaceutical, and biotech industries where sanitation is critical.

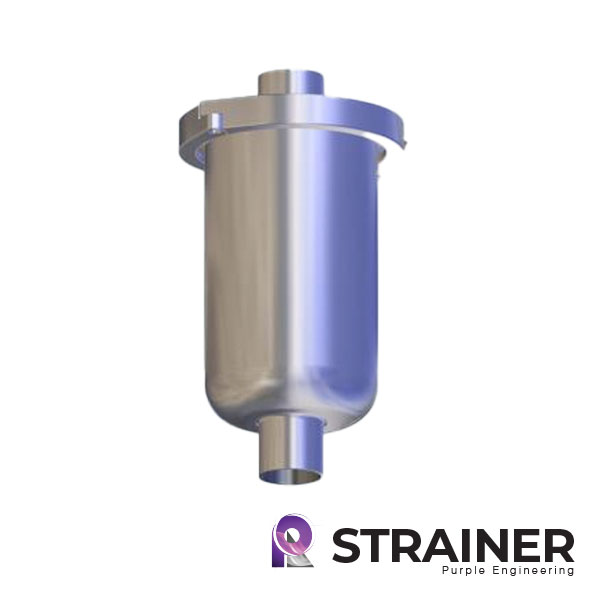

Ace T Type Sanitary Strainer

Robust construction that ensures longevity and resistance to wear and corrosion.