Y Strainers: Providing Essential Protection for Your Piping Systems Maximise Efficiency and Safety with Purple Engineering's Y Strainers

At Purple Engineering, our Y Strainers stand as a testament to our commitment to delivering high-quality filtration solutions. Designed to protect your piping systems from debris and particulate matter, our Y Strainers ensure the smooth operation of your equipment, safeguarding against potential damage and downtime.

Why Y Strainers?

Y Strainers are named for their shape, resembling the letter 'Y', and are engineered to remove solids from flowing liquids or gases through a perforated or wire mesh straining element. They are an essential component in many industrial processes, including water treatment, chemical processing, and HVAC systems, providing a simple yet effective means of protecting critical components such as pumps, meters, and valves.

Request a Quote for Y Strainers

Features and Benefits:

- Versatile Filtration: Suitable for a wide range of applications, our Y Strainers can handle various fluids, from water and oil to steam and gas.

- Durable Construction: Made from high-quality materials, our strainers are built to withstand harsh operating conditions, ensuring longevity and reliability.

- Easy Maintenance: Designed for convenience, our Y Strainers feature a removable straining element, allowing for easy cleaning and minimal system downtime.

- Customisable Options: With a variety of sizes, materials, and end connections available, our Y Strainers can be tailored to meet the specific requirements of your system.

Materials for Replacement Screens and Baskets

Applications:

Our Y Strainers are versatile enough to be used across various industries, providing essential protection in:

- Water Treatment Facilities

- Chemical Processing Plants

- HVAC Systems

- Oil & Gas Production

- Food & Beverage Manufacturing

Pressure Drop Curves for Y Strainers

Why Choose Purple Engineering for Your Y Strainers?

- Expertise: With extensive experience in the filtration industry, we understand the challenges you face and offer solutions that meet your specific needs.

- Quality: Our commitment to quality ensures that every Y Strainer we provide is designed to perform efficiently and reliably.

- Customisation: We offer bespoke solutions, allowing you to specify the size, material, and configuration that best suits your application.

- Support: Our dedicated team is here to assist you from selection through to installation, ensuring you get the most out of your Y Strainer.

Get in Touch with Purple Engineering

Protect your systems and ensure uninterrupted operation with our Y Strainers. Contact Purple Engineering today to discuss your requirements and discover how our solutions can enhance your operations. Our team is ready to assist you in selecting the perfect Y Strainer tailored to your specific needs.

Purple Engineering - Your Trusted Partner in Advanced Filtration Solutions.

Y Strainers Your Premier Source For Strainer Solutions

Mueller 865-CS

The Mueller 865-CS Cast Carbon Steel Y-Strainer is designed for high-pressure and high-temperature applications, ensuring protection for pipelines by straining foreign matter and weld debris.

Mueller 865-SS

The Mueller 865-SS Cast Stainless Steel Y-Strainer is designed for high-pressure and high-temperature applications.

Mueller 866-CS

The Mueller 866-CI Y-Strainer is designed to offer reliable protection for pipelines by effectively straining out foreign matter.

Mueller 866-SS

The Mueller 866-SS Cast Stainless Steel Socket Weld End Y-Strainer offers robust protection for pipelines in high-pressure and high-temperature environments. Ideal for filtering weld debris.

Watts 87SI

The Watts 87SI Stainless Steel Y-Strainer offers robust protection with threaded or socket weld connections, ideal for high-pressure and high-temperature applications.

Watts 88CSI

The Watts 88-CSI Cast Steel Y-Strainer offers robust protection with threaded or socket weld connections, ideal for high-pressure and high-temperature applications.

Watts 88S

The Watts 88S Stainless Steel Y-Strainer offers superior corrosion resistance, ideal for high-pressure and high-temperature applications

Mueller 911U

The Mueller 911U UL approved Y-Strainer effectively prevents clogging in fire service systems, protecting pumps and mechanical equipment.

Mueller CA951

The Mueller CA951 Y-Strainer effectively removes foreign matter from pipelines, protecting pumps and mechanical equipment.

Mueller LF351

The Mueller LF351 Y-Strainer is expertly engineered to ensure the integrity and efficiency of fluid handling systems by removing foreign particles from pipelines.

Mueller LF352

The Mueller LF352 Y-Strainer is expertly engineered to ensure the integrity and efficiency of fluid handling systems by removing foreign particles from pipelines.

Mueller LF358

The Mueller LF358 Y-Strainer is engineered to ensure the integrity and efficiency of fluid handling systems by removing foreign particles from pipelines.

Watts LF777

The Watts LF777 Wye-Pattern Strainer is engineered to ensure the integrity and efficiency of plumbing systems by removing foreign particles from pipelines.

Watts LF777S

The Watts LF777S Wye-Pattern Strainer is engineered to ensure the integrity and efficiency of plumbing systems by removing foreign particles from pipelines.

Watts LF777SI

The Watts LF777SI Wye-Pattern Strainer is engineered to ensure the integrity and efficiency of plumbing systems by removing foreign particles from pipelines. Designed to provide effective and economical protection for pumps, valves, and other costly equipment, these strainers are essential for maintaining system performance and reliability.

Watts P777

The Watts P777 Wye-Pattern Strainer is expertly engineered to ensure the integrity and efficiency of fluid handling systems by removing foreign particles from pipelines.

PVC or CPVC Y Strainers

PVC or CPVC strainers are the perfect choice for in-line removal of suspended solids, sediment, dirt and debris.

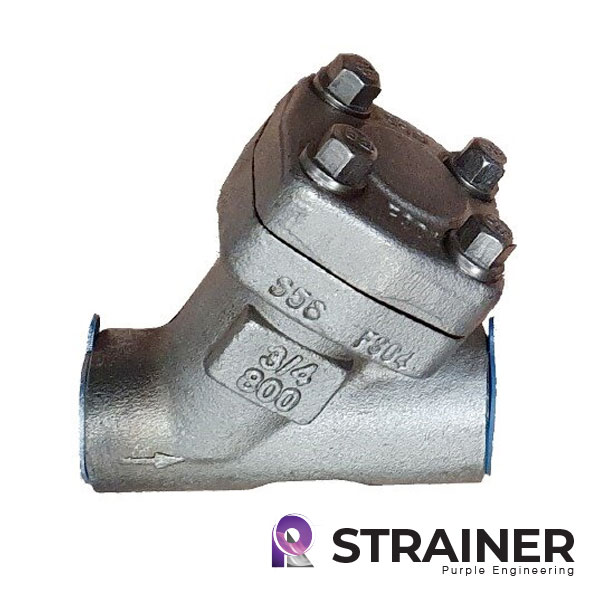

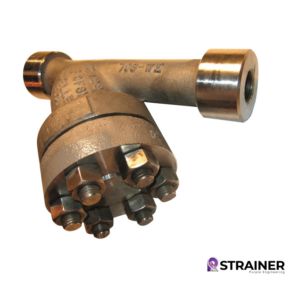

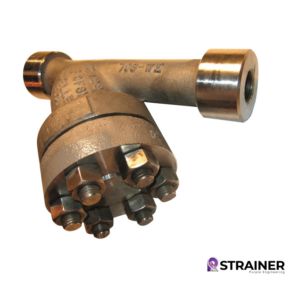

YS82BC-SS

Y Strainer, Stainless Steel, ANSI Class 600, Socket Weld Ends, Bolted Cover, Plugged Blow-off

YS82BC-CS

Y Strainer, Carbon Steel, ANSI Class 600, Socket Weld Ends, Bolted Cover, Plugged Blow-off

YS82-SS

Y Strainer, Stainless Steel, ANSI Class 600, Socket Weld Ends, Gasketed Cap, Plugged Blow-off