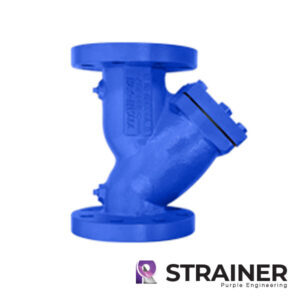

Y Strainers: Providing Essential Protection for Your Piping Systems Maximise Efficiency and Safety with Purple Engineering's Y Strainers

At Purple Engineering, our Y Strainers stand as a testament to our commitment to delivering high-quality filtration solutions. Designed to protect your piping systems from debris and particulate matter, our Y Strainers ensure the smooth operation of your equipment, safeguarding against potential damage and downtime.

Why Y Strainers?

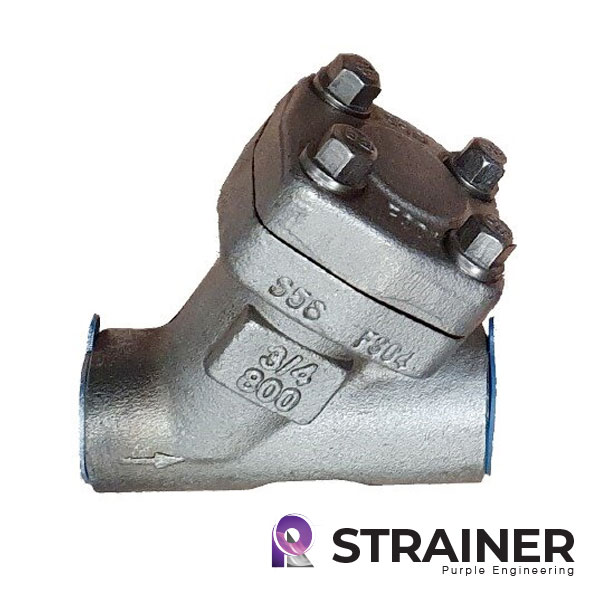

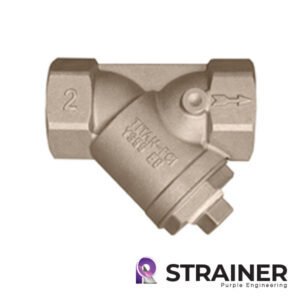

Y Strainers are named for their shape, resembling the letter 'Y', and are engineered to remove solids from flowing liquids or gases through a perforated or wire mesh straining element. They are an essential component in many industrial processes, including water treatment, chemical processing, and HVAC systems, providing a simple yet effective means of protecting critical components such as pumps, meters, and valves.

Request a Quote for Y Strainers

Features and Benefits:

- Versatile Filtration: Suitable for a wide range of applications, our Y Strainers can handle various fluids, from water and oil to steam and gas.

- Durable Construction: Made from high-quality materials, our strainers are built to withstand harsh operating conditions, ensuring longevity and reliability.

- Easy Maintenance: Designed for convenience, our Y Strainers feature a removable straining element, allowing for easy cleaning and minimal system downtime.

- Customisable Options: With a variety of sizes, materials, and end connections available, our Y Strainers can be tailored to meet the specific requirements of your system.

Materials for Replacement Screens and Baskets

Applications:

Our Y Strainers are versatile enough to be used across various industries, providing essential protection in:

- Water Treatment Facilities

- Chemical Processing Plants

- HVAC Systems

- Oil & Gas Production

- Food & Beverage Manufacturing

Pressure Drop Curves for Y Strainers

Why Choose Purple Engineering for Your Y Strainers?

- Expertise: With extensive experience in the filtration industry, we understand the challenges you face and offer solutions that meet your specific needs.

- Quality: Our commitment to quality ensures that every Y Strainer we provide is designed to perform efficiently and reliably.

- Customisation: We offer bespoke solutions, allowing you to specify the size, material, and configuration that best suits your application.

- Support: Our dedicated team is here to assist you from selection through to installation, ensuring you get the most out of your Y Strainer.

Get in Touch with Purple Engineering

Protect your systems and ensure uninterrupted operation with our Y Strainers. Contact Purple Engineering today to discuss your requirements and discover how our solutions can enhance your operations. Our team is ready to assist you in selecting the perfect Y Strainer tailored to your specific needs.

Purple Engineering - Your Trusted Partner in Advanced Filtration Solutions.

Y Strainers Your Premier Source For Strainer Solutions

YS65-SS

Y Strainer, Stainless Steel, ANSI Class 600, Butt Weld Ends Sch. 80, Bolted Cover, Plugged Blow-off

YS65-CS

Y Strainer, Carbon Steel, ANSI Class 600, Butt Weld Ends Sch. 80, Bolted Cover, Epoxy Painted, Plugged Blow-off

YS64-CS

Y Strainer, Carbon Steel, ANSI Class 600, Flanged Ends, Bolted Cover, Epoxy Painted, Plugged Blow-off

YS63-CS

Y Strainer, Carbon Steel, ANSI Class 300, Butt Weld Ends Sch. 40, Bolted Cover, Epoxy Painted, Plugged Blow-off

ACE-YS62-SS

Y Strainer, Stainless Steel, ANSI Class 300, Flanged Ends, Bolted Cover, Plugged Blow-off

ACE-YS62-CS

Y Strainer, Carbon Steel, ANSI Class 300, Flanged Ends, Bolted Cover, Epoxy Painted, Plugged Blow-off

ACE-YS61-CS

Y Strainer, Carbon Steel, ANSI Class 150, Flanged Ends, Bolted Cover, Epoxy Painted, Plugged Blow-off

YS59-CI

Y Strainer, Cast Iron, ANSI Class 250, Flanged Ends, Extra Heavy Body, Bolted Cover, Epoxy Painted, Plugged Blow-off

YS58G-UL-DI

Y Strainer, Ductile Iron, WOG 300, Grooved Ends, Epoxy Painted, Gasketed Caps, Plugged Blow-off, Fire Protection

YS58-DGG

Y Strainer, Ductile Iron, ASME Class 300, Grooved Ends, Epoxy Painted, Gasketed Caps, Plugged Blow-off

YS58-CI

Y Strainer, Cast Iron, ANSI Class 125, Flanged Ends, Bolted Cover, Epoxy Painted, Plugged Blow-off

- « Previous

- 1

- 2